Window Industry Bits

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Window Industry Bits

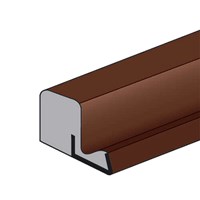

Window Industry Bits are specialist router cutters and accessories designed specifically for the installation, fabrication and maintenance of UPVC, aluminium and composite window systems. MyToolShed.co.uk stocks a comprehensive range of Trend window industry bits, including single flute helical cutters, water slot cutters, weatherseal strip cutters and bearing-guided window board cutters. These precision-engineered tools enable clean, professional cuts in modern window materials without chipping, melting or leaving rough edges.

Whether you're routing drainage slots, cutting weatherseal recesses or trimming window boards, having the correct cutter profile is essential for achieving weathertight seals and professional finishes. The range at MyToolShed includes specialised cutters for Aquamac weatherseal systems in both 21 and 63 profiles, narrow neck helical cutters for restricted access areas, and upcut designs that efficiently evacuate swarf when working with aluminium and UPVC materials.

Applications

Window Industry Bits are essential tools for:

- Window fitters and installers working with UPVC, aluminium and composite frames

- Double glazing companies fabricating and installing modern window systems

- Joiners and carpenters fitting window boards and internal trims

- Building contractors involved in new builds and renovation projects

- Conservatory installers requiring weatherseal and drainage solutions

- Shopfitters installing commercial glazing systems

- Routing water drainage slots in window frame profiles

- Cutting precise recesses for Aquamac, Aquatex and other weatherseal strip systems

- Trimming and profiling UPVC window boards

- Creating clean edges in aluminium cladding and frames

Choosing The Right Window Industry Bits

Selecting the appropriate window industry bit depends on several key factors:

- Material type: Ensure your cutter is designed for the specific material you're working with – UPVC requires different cutting geometry to aluminium to prevent melting or burring

- Profile requirements: Match the cutter profile to your weatherseal system (Aquamac 21, Aquamac 63, Aqua 21, etc.) for accurate recess depths and widths

- Shank diameter: Check compatibility with your router collet – most window industry bits feature 8mm or 1/4" shanks

- Single flute design: Helical single flute cutters provide superior chip clearance when routing synthetic materials, reducing heat build-up and extending cutter life

- Bearing guidance: Bearing-guided cutters offer greater control and consistency when profiling window boards and following template edges

- Access considerations: Narrow neck cutters are essential for reaching into tight corners and restricted areas of window frames

Safety Information

Always wear appropriate PPE including safety glasses and hearing protection when using router cutters. Ensure your router is disconnected from the mains power supply before changing bits. Use routers at the correct speed settings for the material and cutter diameter – excessive speeds can cause melting in UPVC. Secure workpieces firmly and maintain a stable working position. Keep cutters sharp to reduce cutting forces and improve finish quality.

Frequently Asked Questions

What's the difference between upcut and straight flute cutters for window work?

Upcut helical cutters feature a spiral design that lifts swarf away from the cutting area, making them ideal for deeper cuts and aluminium work where chip evacuation is critical. Straight flute cutters provide a cleaner bottom finish and are often preferred for shallow weatherseal recesses in UPVC.

Can I use standard router bits for UPVC windows?

While possible, specialist window industry bits are specifically designed with cutting geometries, flute configurations and coatings optimised for synthetic materials. They run cooler, last longer and produce superior finishes compared to standard woodworking router bits when working with UPVC and aluminium.

How do I know which Aquamac cutter profile I need?

Check the weatherseal strip you're using – the most common profiles are Aquamac 21 (smaller profile) and Aquamac 63 (larger profile). The cutter designation matches the strip system, ensuring the routed recess provides the correct depth and width for a weathertight seal.