Turning Tools

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Turning Tools

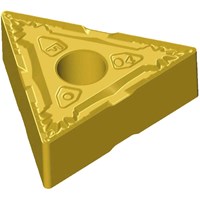

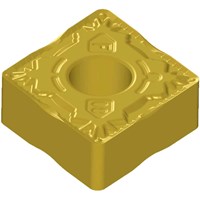

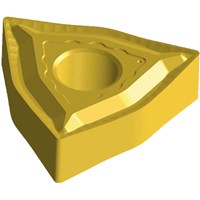

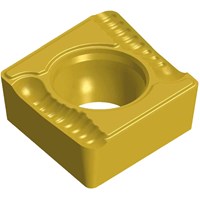

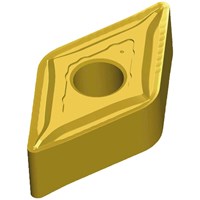

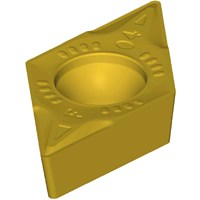

Turning tools are precision cutting instruments designed for use with lathes to shape, cut and finish metal, wood and other materials through rotational machining. At MyToolShed.co.uk, our turning tools category encompasses high-quality tool holders and carbide inserts that provide the foundation for accurate and efficient turning operations. These components work together to deliver professional results across a wide range of turning applications, from fine detail work to heavy-duty material removal.

Whether you're working with a manual lathe in a traditional machine shop or operating CNC equipment in a modern production environment, the right combination of holders and inserts is essential for achieving precise dimensions, excellent surface finishes and optimal tool life. MyToolShed stocks turning tools suitable for both industrial metalworking professionals and serious workshop enthusiasts who demand reliable performance.

Applications

Turning tools are essential equipment for:

- Machine shops and precision engineering firms producing components to tight tolerances

- General engineering workshops handling repair, modification and fabrication work

- Manufacturing facilities with production lathes for batch and volume production

- Maintenance and repair operations in automotive, aerospace and industrial sectors

- Tool and die makers creating specialist tooling and fixtures

- Educational institutions teaching machining skills and manufacturing processes

- Hobbyists and model engineers working with home workshop lathes

- Metal turners producing one-off parts and prototype components

Choosing The Right Turning Tools

Selecting appropriate turning tools depends on several key factors. Consider the workpiece material you'll be machining – ferrous metals, non-ferrous alloys, plastics and composites each require different insert grades and geometries. The type of operation is equally important, whether you're facing, profiling, grooving, threading or parting off.

Tool holder compatibility with your lathe is crucial – check the shank size and mounting system matches your machine's tool post. For insert tooling, consider the insert shape and size appropriate for your application, with larger inserts generally offering better rigidity and tool life for heavy cuts, whilst smaller inserts provide better access for intricate work.

The insert grade and coating significantly affects performance and longevity. Carbide grades are selected based on workpiece material hardness and cutting conditions, with various coatings enhancing wear resistance and allowing higher cutting speeds. MyToolShed.co.uk offers turning tools from reputable manufacturers that deliver consistent quality and performance.

Safety Information

Always ensure turning tools are securely clamped in the tool holder and positioned at the correct height relative to the workpiece centre line. Inspect inserts for chips or cracks before use and replace damaged cutting edges immediately. Wear appropriate personal protective equipment including safety glasses and avoid loose clothing or jewellery that could catch in rotating machinery. Follow your lathe manufacturer's guidelines for maximum spindle speeds and ensure workpieces are properly secured in the chuck or between centres.

Frequently Asked Questions

What's the difference between brazed and indexable turning tools?

Brazed tools have a permanent carbide tip fixed to the tool body and require grinding to resharpen. Indexable tools use replaceable inserts that can be rotated or changed when worn, offering convenience and consistent cutting edge geometry without specialist grinding equipment.

How do I know when to replace a carbide insert?

Replace inserts when you notice increased cutting forces, poor surface finish, excessive vibration or visible wear on the cutting edge. Most inserts have multiple cutting edges – simply rotate to a fresh edge when one becomes worn.

Can I use the same turning tools for steel and aluminium?

Whilst some general-purpose inserts work adequately with multiple materials, optimal results come from using material-specific grades and geometries. Aluminium typically requires sharper cutting edges and different rake angles compared to steel machining.