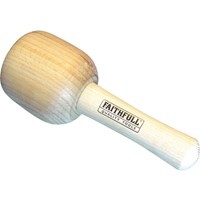

Mallets

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Mallets

Mallets are essential striking tools designed to deliver controlled, softer blows compared to traditional hammers, making them ideal for applications where protecting delicate surfaces is paramount. Unlike metal-faced hammers, mallets feature heads made from materials such as rubber, plastic, or wood that absorb impact and prevent damage to workpieces. MyToolShed.co.uk stocks a comprehensive range of mallets suitable for professional tradespeople and DIY enthusiasts across woodworking, construction, flooring, and automotive sectors.

Our mallet category includes plastic mallets for assembly work and engineering tasks, rubber mallets for flooring installation and panel fitting, and wooden mallets for traditional woodworking and chisel work. Each type offers distinct advantages depending on the material being worked and the required impact force, ensuring you'll find the right tool for your specific application at MyToolShed.co.uk.

Applications

Mallets serve diverse trades and industries including:

- Woodworking and Joinery: Driving chisels, assembling furniture, and tapping joints without marking timber

- Flooring Installation: Fitting laminate, engineered wood, and parquet flooring systems

- Automotive and Panel Beating: Gentle metal shaping and trim installation

- Construction and Building: Installing plasterboard, positioning tiles, and general assembly tasks

- Masonry: Tapping bricks and blocks into position without damage

- Engineering and Manufacturing: Assembly work requiring non-marring strikes

- Upholstery and Leatherwork: Setting fasteners and shaping materials

Choosing The Right Mallets

Selecting the appropriate mallet depends on several key factors:

- Head Material: Rubber mallets offer versatility for general construction and flooring; plastic mallets provide firm strikes for assembly without surface damage; wooden mallets deliver traditional performance for woodworking and chisel work

- Head Weight: Lighter heads (200-400g) suit precision work and delicate materials, whilst heavier options (500g+) provide greater impact force for demanding applications

- Handle Material: Fibreglass and composite handles offer durability and shock absorption, whilst wooden handles provide traditional feel and balance

- Handle Length: Shorter handles give greater control for detailed work; longer handles increase striking force for heavier applications

- Face Diameter: Larger striking faces distribute force across wider areas, reducing the risk of localised damage

Safety Information

Always inspect your mallet before use, checking for split handles, loose heads, or damaged striking faces. Wear appropriate eye protection to guard against flying debris or material fragments. Ensure a firm grip and maintain proper stance to prevent missed strikes. Replace mallets showing signs of wear, particularly split wooden handles or degraded rubber faces that could fail during use.

Frequently Asked Questions

What's the difference between a rubber mallet and a plastic mallet?

Rubber mallets feature softer, more flexible heads that absorb impact well, making them ideal for flooring installation and general construction where surface protection is crucial. Plastic mallets have firmer heads that deliver more precise strikes with less rebound, preferred for assembly work and engineering applications.

Can I use a wooden mallet with chisels?

Yes, wooden mallets are specifically designed for chisel work in traditional woodworking. Their wooden heads won't damage chisel handles and provide controlled striking force, making them the preferred choice for carving and joinery tasks.

How do I maintain my mallet?

Keep striking faces clean and free from debris. Store in a dry environment to prevent wooden handles from warping or splitting. Check regularly for loose heads and tighten or replace as necessary. Replace worn rubber or plastic heads when they become damaged or lose their shape.