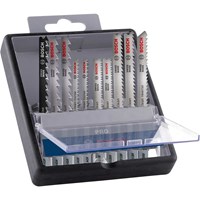

Jigsaw Blades

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Jigsaw Blades

Jigsaw blades are essential consumable accessories that determine the cutting performance, precision and finish quality of your jigsaw. At MyToolShed.co.uk, we stock an extensive range of jigsaw blades from Bosch Professional and other leading manufacturers, designed to tackle everything from softwood and hardwood to metal, plastics, ceramics and composite materials. Whether you're cutting intricate curves in laminate worktops, making plunge cuts in floorboards, or slicing through sheet metal, selecting the right blade for the material and application is crucial for achieving professional results.

Modern jigsaw blades come in various tooth configurations, materials and shank types to suit different jigsaws and cutting requirements. High Carbon Steel (HCS) blades are ideal for softwood and general-purpose work, while High Speed Steel (HSS) and Bi-Metal blades offer the durability needed for metal cutting. For demanding applications involving abrasive materials like tiles or fibreglass, carbide-tipped blades provide exceptional longevity. Understanding the differences between blade types, tooth patterns and TPI (teeth per inch) ratings will help you achieve cleaner cuts, reduce splintering and extend blade life across your projects.

Applications

Jigsaw blades are used across numerous trades and applications:

- Joiners and Carpenters: Cutting curves, creating worktop cut-outs and precision woodworking

- Kitchen Fitters: Cutting sink apertures and hob openings in laminate and solid wood worktops

- Flooring Specialists: Trimming laminate, engineered wood and vinyl flooring around architraves

- Electricians and Plumbers: Cutting access holes in floorboards and plasterboard for cable runs and pipework

- Shopfitters: Creating custom shapes and cut-outs in display materials and fixtures

- Metal Fabricators: Cutting sheet metal, profiles and thin-gauge steel components

- DIY Enthusiasts: Home improvement projects involving furniture making and general woodworking

Choosing The Right Jigsaw Blades

Material Being Cut: This is your primary consideration. Wood-cutting blades typically use HCS construction with larger teeth, whilst metal-cutting blades require HSS or Bi-Metal construction with finer teeth. For abrasive materials like tiles or cement board, carbide-grit blades are essential.

Teeth Per Inch (TPI): Lower TPI (3-6) offers fast cutting in softwood but leaves rougher edges. Medium TPI (6-10) provides balance for general hardwood work. High TPI (10-20+) delivers slower, cleaner cuts essential for metals and plastics.

Blade Length: Choose a blade at least 10-15mm longer than your material thickness. Standard blades range from 75mm to 150mm, with longer blades necessary for thick timber or worktops.

Shank Type: Modern jigsaws predominantly use T-shank fittings for tool-free blade changes, whilst older models may require U-shank blades. Always verify your jigsaw's compatibility before purchasing.

Specialist Blades: Consider reverse-tooth blades for laminate worktops to minimise top-surface splintering, or narrow scrolling blades for tight radius curves.

Safety Information

Always disconnect your jigsaw from the 240v power supply or remove the battery before changing blades. Wear appropriate eye protection, as the cutting action can throw debris upwards. Dust masks should be worn when cutting MDF, treated timber or composite materials that produce harmful dust.

Inspect blades before fitting and discard any showing damage, missing teeth or cracks. Never force a worn blade to continue cutting—dull blades require excessive pressure, increasing the risk of the tool slipping or binding. Ensure workpieces are properly secured with clamps before cutting, and maintain firm control of the jigsaw with both hands.

Frequently Asked Questions

How often should I replace jigsaw blades?

Replace blades as soon as you notice reduced cutting performance, excessive vibration or visible damage to teeth. A sharp blade requires minimal pressure—if you're forcing the tool or noticing rough edges, it's time for a new blade. Professional tradespeople may replace blades after just a few hours when cutting harder materials.

Can I use the same blade for different materials?

Whilst multi-material blades exist, you'll achieve better results and longer blade life by using material-specific blades. MyToolShed.co.uk stocks specialist blades for wood, metal and composite materials to ensure optimal performance for every application.

How can I reduce splintering when cutting laminate?

Use a reverse-tooth blade specifically designed for laminate, which cuts on the downstroke to protect the top surface. Apply masking tape along your cut line and ensure your blade is sharp. An anti-splinter insert fitted to your jigsaw provides additional support around the blade.