Inserts

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Inserts

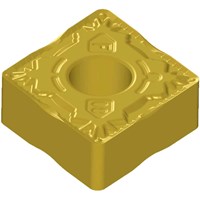

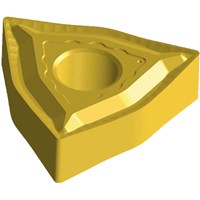

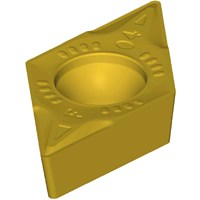

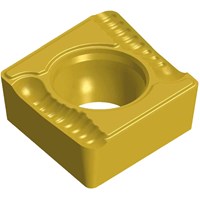

Lathe tool inserts are precision-engineered cutting components designed for indexable turning tools, offering a practical and economical solution for metalworking operations. Unlike traditional brazed tools, these carbide inserts can be quickly replaced or rotated when worn, eliminating regrinding and minimising downtime. MyToolShed.co.uk stocks a comprehensive range of inserts including complete indexable turning tool sets in 8mm and 10mm shank sizes, individual replacement insert packs, and specialised inserts for turning, threading, and milling operations from trusted brands including Sealey and Sirius.

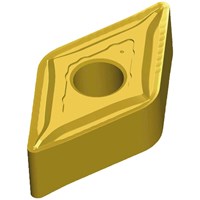

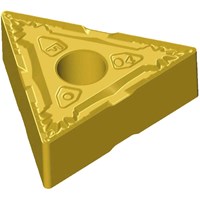

Available in various geometries and coatings, these inserts suit different materials and machining operations commonly encountered in UK engineering workshops. The indexable system provides excellent value—you only replace the small carbide insert rather than the entire tool holder, making it an economical choice for both professional machinists and serious hobbyists working with steel, aluminium, brass, and other machinable metals.

Applications

Lathe tool inserts are essential equipment for a diverse range of metalworking professionals and applications:

- Engineering Machinists – producing precision components in job shops and production facilities

- Model Engineers – hobbyists working on miniature engines and mechanical models

- Tool and Die Makers – creating custom tooling, moulds, and precision fixtures

- Maintenance Fitters – repairing or fabricating replacement parts in industrial settings

- Automotive Restoration Specialists – manufacturing hard-to-find parts for classic vehicles

- Agricultural Engineers – repairing farm machinery components

- Educational Institutions – technical colleges teaching machining skills

- Prototyping Workshops – creating one-off components for product development

Choosing The Right Inserts

Shank Size Compatibility: Match the tool holder to your lathe's tool post. Smaller bench lathes typically use 8mm shanks, whilst larger machines accommodate 10mm or greater. Verify your lathe specifications before purchasing to ensure proper fitment and rigidity.

Material and Operation Type: Different insert grades suit specific materials—general-purpose carbide handles mild steel, aluminium, and brass, whilst coated inserts extend tool life on harder materials. Consider whether you need inserts for external turning, facing, threading, or grooving operations.

Insert Economy: Look for inserts with multiple cutting edges that can be indexed when one edge wears. Triangular and square inserts typically offer three or four usable corners, maximising value. MyToolShed.co.uk offers complete indexable sets for new setups and replacement insert packs for refreshing existing tool holders economically.

Surface Finish Requirements: Inserts with smaller nose radii and positive rake angles produce finer finishes, whilst robust geometries prioritise material removal for roughing operations.

Safety Information

Personal Protective Equipment: Always wear safety glasses or a full face shield when operating lathes. Avoid loose clothing, jewellery, and secure long hair to prevent entanglement in rotating components.

Insert Installation: Ensure inserts are properly seated and securely clamped before starting the lathe. Loose inserts can be ejected at high velocity. Check clamping screws are tightened to the correct torque specification.

Chip Handling: Never remove chips whilst the lathe is running. Stop the machine completely and use brushes or chip hooks rather than hands to clear sharp metal swarf.

Frequently Asked Questions

How many cutting edges does a typical insert have?

Most triangular or square inserts feature three or four usable corners that can be indexed as each edge wears, providing excellent economy compared to solid tool bits requiring regrinding.

What's the difference between 8mm and 10mm turning tool sets?

The measurement refers to the tool holder shank size. 8mm sets suit smaller bench lathes and miniature work, whilst 10mm holders provide greater rigidity for larger machines and heavier cutting. Always match the shank size to your lathe's tool post capacity.

Can I use the same inserts for steel and aluminium?

General-purpose carbide inserts can machine both materials adequately. For optimal results, aluminium benefits from sharper rake angles whilst steel requires more robust edge preparation, but standard inserts perform well for occasional use across different materials.