Grinding Discs

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Grinding Discs

Grinding discs are essential abrasive accessories designed for use with angle grinders, enabling precise material removal, surface preparation, and finishing work across metal, stone, and masonry. Unlike thin cutting discs that slice through materials, grinding discs feature thicker construction that allows controlled stock removal across broader surface areas. Whether removing welding seams, smoothing concrete, deburring fabrication work, or preparing surfaces for painting, the right grinding disc delivers professional results with improved efficiency and safety.

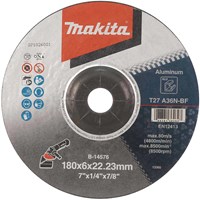

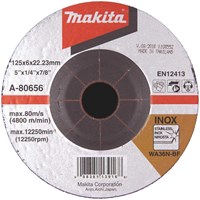

MyToolShed.co.uk stocks a comprehensive range including depressed centre grinding discs, diamond grinding wheels, and specialised discs for various materials. Available in common sizes including 115mm and 125mm grinding discs, the selection features trusted brands such as Bosch Professional, Makita, Faithfull, and Draper. Modern innovations like Bosch's X-Lock system offer tool-free disc changes for enhanced productivity, whilst expert-grade diamond grinding heads provide exceptional longevity when working with demanding materials like reinforced concrete and natural stone.

Applications

Grinding discs are indispensable across numerous trades and applications:

- Welders and Fabricators: Cleaning welds, removing spatter, bevelling edges, and preparing joints

- Steel Erectors and Metal Workers: Surface preparation, deburring, and shaping structural steelwork

- General Builders: Grinding back concrete, removing mortar, and site preparation work

- Automotive and Body Repair: Paint removal, rust elimination, and panel preparation

- Plumbers and Heating Engineers: Cleaning pipework and preparing surfaces for welding

- Stone Masons and Tilers: Shaping and finishing stone, concrete, and masonry surfaces

- Maintenance Engineers: Removing corrosion and equipment refurbishment

- DIY Enthusiasts: Home metalwork projects and restoration work

Choosing The Right Grinding Discs

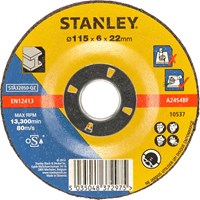

Match Disc Size to Your Grinder: Grinding discs must match your angle grinder's diameter—typically 115mm, 125mm, or 230mm. Never use an incorrectly sized disc.

Select for Material Type: Metal grinding discs feature aluminium oxide abrasives, whilst stone and concrete require diamond grinding wheels. For stainless steel work, always choose inox-specification discs to prevent contamination.

Consider Grit Rating: Coarser grits like A24 remove material quickly but leave rougher finishes, ideal for heavy stock removal. Finer grits such as A30T provide smoother finishes for final surface preparation.

Check Maximum RPM Rating: The disc's maximum RPM must meet or exceed your grinder's no-load speed. This is critical for safety—exceeding rated RPM can cause catastrophic disc failure.

Professional vs Economy Grade: Professional discs from brands like Bosch Expert and Makita Pro feature superior abrasive formulations that cut faster and last longer, offering better value through improved productivity.

Quick-Change Systems: MyToolShed.co.uk stocks Bosch's X-Lock system, which eliminates spanners for disc changes, significantly improving site efficiency.

Safety Information

Personal Protective Equipment: Always wear safety glasses or face shield, hearing protection, sturdy work gloves, and respiratory protection when grinding generates dust.

Inspect Before Use: Check every disc for cracks or damage before mounting. A damaged disc can disintegrate at high speed with catastrophic consequences.

Observe Use-By Dates: Never use discs beyond their expiry date. Bonding agents deteriorate over time, particularly in damp conditions, compromising disc integrity.

Maintain Proper Angle: For depressed centre discs, maintain 15-30 degrees to the workpiece. Never use the flat face of a depressed centre grinding disc.

Frequently Asked Questions

What's the difference between cutting and grinding discs?

Grinding discs are significantly thicker (typically 6mm) and designed for material removal across surfaces, whilst cutting discs are thin (1-3mm) and designed to slice through materials. Using one for the other's purpose is dangerous and will damage the disc.

Can I use metal grinding discs on stone or concrete?

No. Metal grinding discs use aluminium oxide abrasives which are ineffective on masonry and quickly become clogged. Stone, concrete, and masonry require diamond grinding wheels featuring industrial diamonds bonded to the disc surface.

Do I need different discs for stainless steel?

Yes. Standard grinding discs contain iron particles that contaminate stainless steel surfaces and cause rust spots. Always use inox-specification grinding discs when working with stainless steel to maintain its corrosion-resistant properties.