Grinder Wheel Brushes

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Grinder Wheel Brushes

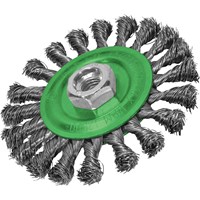

Grinder wheel brushes are high-performance rotary attachments designed to mount directly onto angle grinders for aggressive surface preparation, rust removal and cleaning tasks. Available in crimped wire and twisted knot configurations, these essential accessories deliver rapid material removal across metalworking, fabrication and restoration applications. MyToolShed.co.uk stocks grinder wheel brushes from leading manufacturers including Lessmann, Bosch Professional, Faithfull, Sealey and Blue Spot, offering options for everything from light surface conditioning to heavy-duty scale and paint removal.

The category encompasses various wire materials and brush profiles to suit different applications. Crimped wire wheel brushes feature flexible wires ideal for lighter cleaning and reaching into recesses, whilst twisted knot designs provide aggressive material removal on heavily corroded surfaces. Specialist options include stainless steel (Inox) brushes for working on stainless steel without contamination risk, and modern X-LOCK quick-change systems compatible with the latest Bosch and Faithfull angle grinders for tool-free accessory changes on site.

Applications

Grinder wheel brushes are essential tools across numerous trades and industries:

- Welders and Fabricators: Pre-weld surface preparation, weld spatter removal and seam cleaning

- Metal Finishers: Deburring, surface texturing and consistent finish creation on metalwork

- Automotive Technicians: Chassis restoration, rust removal, paint stripping and engine component cleaning

- Construction Workers: Steelwork preparation, removing corrosion from structural elements and cleaning fixings

- Maintenance Engineers: Equipment refurbishment, descaling pipes and machinery, industrial cleaning

- Agricultural Engineers: Farm machinery restoration, rust removal and metal implement maintenance

- Marine Engineers: Combating saltwater corrosion, boat building and maintenance surface preparation

- DIY Enthusiasts: Home metalwork projects, garden furniture restoration and general metal preparation

Choosing The Right Grinder Wheel Brushes

Wire Type: Select crimped wire brushes for lighter cleaning and surface preparation where minimal scratching is desired. Choose twisted knot brushes for aggressive material removal on heavily rusted or painted surfaces. Always use stainless steel (Inox) brushes when working on stainless steel to prevent ferrous contamination and subsequent corrosion.

Brush Profile: Flat wheel brushes excel at edge work and accessing corners, whilst cup brushes cover larger flat areas quickly. Conical and bevelled designs offer versatility for both flat surfaces and tight spaces.

Speed Rating: Always verify the maximum RPM rating marked on the brush exceeds your angle grinder's no-load speed. Standard 115mm grinders typically operate at 10,000-12,000 RPM. Using brushes below their rated speed risks catastrophic failure and serious injury.

Mounting System: Traditional M14 threaded mounting fits most angle grinders. X-LOCK systems available from MyToolShed.co.uk provide tool-free changes if you have compatible equipment, ideal for professionals changing accessories frequently throughout the day.

Application Intensity: Occasional DIY users will find excellent value in Blue Spot or Sealey options, whilst professional tradespeople working daily should invest in premium Lessmann or Bosch Professional brushes for superior wire retention and longer service life.

Safety Information

Speed Rating Compliance: Never exceed the maximum RPM marked on the brush. Operating above rated speed can cause catastrophic disintegration, sending wire fragments flying at dangerous velocities. Always match brush specifications to your grinder before mounting.

Personal Protective Equipment: Eye protection meeting EN166 standards is mandatory – full-face visors provide superior protection. Heavy duty gloves prevent puncture wounds, whilst respiratory protection is essential when removing rust or paint that generates harmful dust particles.

Inspection and Mounting: Examine brushes before each use for wire damage or wear. Ensure secure mounting with brushes fully threaded onto the grinder arbor. For X-LOCK systems, verify the brush has clicked into position and pull-test before powering on. Allow the grinder to reach full speed before workpiece contact and apply moderate pressure only – excessive force accelerates wear and increases breakage risk.

Frequently Asked Questions

What's the difference between crimped and knotted wire brushes?

Crimped wire brushes use fine, flexible wires suitable for lighter cleaning and surface preparation without excessive material removal. Knotted (twisted knot) brushes employ thicker wires twisted into bundles for aggressive removal of heavy rust, scale and paint. Choose crimped for finishing work and sensitive surfaces, knotted for heavy-duty applications.

Can I use standard steel wire brushes on stainless steel?

No, never use carbon steel wire brushes on stainless steel surfaces. Carbon steel particles embed during brushing, causing ferrous contamination that leads to rust spots and corrosion. Always use dedicated stainless steel (Inox) wire brushes when working with stainless steel to maintain its corrosion-resistant properties.

Are X-LOCK grinder wheel brushes worth the investment?

For professional tradespeople changing accessories frequently, X-LOCK systems offer significant productivity benefits by eliminating spanners and reducing changeover time to seconds. However, X-LOCK brushes only fit compatible grinders from manufacturers like Bosch and Faithfull. If using traditional angle grinders or changing brushes infrequently, standard M14 threaded brushes offer excellent value and identical performance once mounted.