Grinder Brushes

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Grinder Brushes

Grinder brushes are versatile power tool accessories that transform angle grinders, bench grinders, and die grinders into powerful surface preparation tools. Essential for metalworkers, fabricators, welders, and maintenance engineers, these attachments effectively remove rust, paint, weld spatter, scale, and corrosion from metal surfaces. MyToolShed.co.uk stocks a comprehensive range of grinder brushes available in steel, stainless steel, and brass wire configurations to suit different materials and applications.

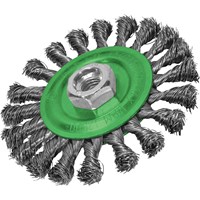

This category includes two main types: cup brushes, which feature bristles arranged in a cup-shaped configuration ideal for flat surfaces and edge work, and wheel brushes, with bristles radiating outward from a central hub perfect for corners, crevices, and intricate metalwork. Available in crimped wire for gentler cleaning or knotted wire for aggressive material removal, grinder brushes from leading brands like Makita, DeWalt, and Bosch are designed to withstand demanding professional use whilst operating safely at high rotational speeds.

Applications

Grinder brushes are indispensable tools across numerous trades and industries:

- Welders and Fabricators – removing weld spatter, cleaning weld seams, and preparing surfaces before welding

- Metal Workers – deburring cut edges, surface preparation, and general metal cleaning

- Maintenance Engineers – removing rust and corrosion from machinery and cleaning threaded components

- Motor Vehicle Technicians – cleaning exhaust systems and preparing bodywork for repair

- Construction Workers – cleaning structural steelwork and preparing metal for painting

- Plumbers and Heating Engineers – cleaning pipework and removing scale from fittings

- Agricultural Engineers – maintaining and refurbishing farm machinery affected by rust

- DIY Enthusiasts – home restoration projects, garden furniture renovation, and general metalwork maintenance

Choosing The Right Grinder Brushes

Brush Type: Cup brushes excel at cleaning flat surfaces and large areas, whilst wheel brushes are better suited for corners, recessed areas, and pipework. Consider which configuration matches your typical applications.

Wire Material: Carbon steel wire suits general steel and iron work economically. Stainless steel brushes are essential when working on stainless steel to prevent contamination. Brass wire brushes are ideal for softer metals like aluminium and copper, and for spark-sensitive environments.

Wire Configuration: Crimped wire provides gentler action for light rust removal and cleaning without excessive material removal. Knotted wire delivers aggressive cutting performance for heavy scale and stubborn corrosion but may mark softer base metals.

Size and Fitment: Ensure the brush diameter suits your grinder size and that the arbor thread matches your tool (M14 is standard for most UK angle grinders). Always verify the maximum RPM rating exceeds your grinder's operating speed. MyToolShed.co.uk offers grinder brushes compatible with 115mm, 125mm, and 230mm grinders.

Safety Information

Always wear appropriate PPE including safety goggles or full face shield rated to BS EN 166, as wire bristles can break off during use and cause serious eye injuries. Heavy-duty work gloves and hearing protection are essential. Before use, inspect brushes for damage including bent wires, cracks, or signs of overheating. Never exceed the maximum RPM rating marked on the brush as this can cause catastrophic failure.

Maintain a firm two-handed grip and position yourself to the side of the brush, never directly behind it. Apply only moderate pressure and work in well-ventilated areas, as wire brushing generates significant dust. Be aware that brushes can catch on edges causing kickback, so approach corners with caution. Ensure workpieces are securely clamped and keep flammable materials clear as sparks are generated during use.

Frequently Asked Questions

Can I use the same grinder brush on stainless steel and mild steel?

Avoid using carbon steel brushes on stainless steel as this causes contamination leading to rust spots and corrosion. Always use dedicated stainless steel wire brushes when working with stainless steel or non-ferrous metals to prevent cross-contamination. Keep separate brushes clearly marked for different materials.

What's the difference between crimped and knotted wire brushes?

Crimped wire brushes have wavy, flexible bristles providing gentler brushing action ideal for general cleaning and light rust removal. Knotted wire brushes feature wire strands twisted in knots, creating a more aggressive tool that removes material faster and suits heavy-duty applications like thick scale and stubborn weld spatter, though they may mark softer metals.

Why do wires keep breaking off my grinder brush?

Excessive wire breakage typically indicates operating above the maximum RPM rating, applying too much pressure, or using incorrect brush angle. Ensure your grinder's speed doesn't exceed the brush's rating, apply only moderate pressure, and maintain the correct working angle – approximately 15-30 degrees for cup brushes and 90 degrees for wheel brushes.