Engraving Cutters

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Engraving Cutters

Engraving cutters are precision router bits designed for creating detailed decorative patterns, lettering, and intricate detail work in wood, plastics, and composite materials. Available in various profiles including V-groove, ball nose, conical, and spiral configurations, these specialised cutters transform standard routers into versatile engraving tools capable of producing professional signage, custom engravings, and decorative elements with exceptional accuracy. MyToolShed.co.uk stocks a comprehensive range of engraving router cutters from Trend, featuring both tungsten carbide tipped (TCT) and solid tungsten carbide (STC) construction for superior edge retention and heat resistance.

Professional-grade engraving cutters come in single, double, and triple flute configurations to suit different applications. Single flute cutters provide maximum precision for delicate detail work, whilst double and triple flute designs offer faster material removal with improved chip clearance for production work. Specialist options like the Rotatip system allow for adjustable engraving depths, whilst mini engravers with spiral upcut and downcut geometries deliver clean finishes in acrylic and plastic materials without melting or chipping.

Applications

- Signwriters creating professional lettering and logos on wooden and acrylic signs

- Joiners and cabinetmakers adding decorative inlays and custom branding to furniture

- Shopfitters producing bespoke retail displays and branded fixtures

- Memorial masons engraving commemorative plaques and wooden memorials

- Model makers requiring precise three-dimensional detail work

- Luthiers creating decorative inlays and ornamental details on musical instruments

- Hobbyists and woodturners personalising projects with custom engravings

- Trophy manufacturers engraving presentation plaques and awards

- Plastic fabricators working with acrylic, polycarbonate, and composite materials

Choosing The Right Engraving Cutters

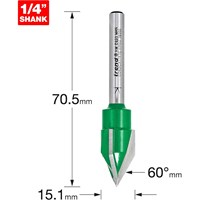

Cutter Profile: Select V-groove cutters for lettering and decorative lines, with angles ranging from 45° to 90° depending on design requirements. Ball nose cutters excel at three-dimensional relief work and curved details, whilst conical profiles offer versatility for both detailed and broader engraving tasks.

Material Compatibility: Acrylic and plastics require two-flute or triple-flute cutters with polished flutes to prevent melting. Hardwoods demand solid tungsten carbide construction for durability, whilst softwoods and MDF work effectively with standard TCT engravers. MyToolShed.co.uk's Trend engraving cutters include specialist options designed specifically for different material types.

Flute Configuration: Single flute cutters provide maximum precision for intricate work, whilst double and triple flute designs remove material faster with better chip evacuation. For plastics, choose spiral upcut cutters for deep engravings or downcut configurations for cleaner surface finishes.

Shank Size and Router Compatibility: Ensure your engraving cutter's shank diameter matches your router's collet size—typically 6mm or 8mm for light-duty work. Never use adaptor sleeves, and verify your router's maximum RPM rating suits the cutter's specifications for safe operation.

Safety Information

Engraving cutters operate at extremely high speeds (10,000-25,000 RPM), creating significant risks if used incorrectly. Always wear safety glasses, hearing protection, and ensure dust extraction is in place, as fine particles present respiratory hazards. Follow HSE guidelines for hand-held power tool use with adequate ventilation.

Never exceed the manufacturer's maximum RPM rating, as this can cause catastrophic bit failure. Always disconnect from 240v mains power before changing cutters, and ensure collets are properly tightened. Inspect cutters before each use for damage—discard any chipped or cracked bits immediately. Secure workpieces firmly, as lateral forces during engraving can cause materials to shift unexpectedly.

Frequently Asked Questions

Can I use engraving cutters in a standard router?

Yes, most engraving cutters work perfectly in standard plunge routers or trim routers, provided the shank diameter matches your collet size and the router offers variable speed control. Smaller diameter cutters perform best at higher RPM settings (18,000-25,000 RPM), so electronic speed control is advantageous. For production work, a router table provides better control and visibility.

How do I prevent burning when engraving plastics?

Use sharp, polished flute cutters specifically designed for plastics—available from MyToolShed.co.uk in two and three flute configurations. Increase your feed rate whilst keeping router speed moderate (12,000-16,000 RPM). Make multiple shallow passes rather than full depth cuts, and ensure effective dust extraction to remove hot chips quickly.

What router speed should I use for engraving work?

Small diameter engravers (under 3mm) perform best at 20,000-25,000 RPM in hardwoods. Larger V-groove and ball nose cutters work well at 16,000-20,000 RPM. For plastics and acrylics, reduce speed to 12,000-16,000 RPM to prevent melting. Always start conservatively and adjust based on finish quality—cutters should produce fine, consistent chips rather than dust or large chunks.