Electrical Lockout Equipment

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Electrical Lockout Equipment

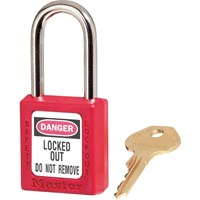

Electrical lockout equipment provides essential safety protection for workers performing maintenance, repairs or servicing on electrical systems. These lockout/tagout (LOTO) devices physically prevent circuits from being re-energised whilst work is in progress, helping to comply with HSE regulations and preventing potentially fatal accidents. MyToolShed.co.uk stocks a comprehensive range of electrical lockout solutions including circuit breaker lockouts, lockout hasps, safety padlocks, danger tags, and complete lockout kits from trusted manufacturers such as Master Lock, Abus, Sealey, and Draper.

From individual lockout devices for sole traders to group lockout hasps enabling multiple workers to secure the same isolation point, our electrical lockout equipment accommodates various applications. Whether you need a portable electricians safety lockout kit in a carry case or wall-mounted lockout stations for fixed workshop locations, you'll find products designed for miniature circuit breakers (MCBs) through to large industrial switchgear, all featuring high-visibility colours and durable construction for demanding environments.

Applications

Electrical lockout equipment is essential for various trades and industries requiring safe electrical isolation:

- Electricians and Electrical Contractors - Daily use during installation, maintenance and repair work on 240v circuits and distribution boards

- Maintenance Engineers - Multi-skilled technicians in manufacturing, facilities management and industrial settings

- Health and Safety Officers - Implementing and monitoring LOTO procedures across organisations

- Factory and Plant Operators - Maintenance teams safely isolating machinery before servicing

- Facilities Managers - Building services maintenance in commercial premises, hospitals, schools and public buildings

- Construction Site Managers - Overseeing electrical work and ensuring safe isolation procedures

- Building Services Engineers - Maintaining HVAC, lighting and power distribution systems

- Renewable Energy Technicians - Servicing solar panel installations and other renewable systems

Choosing The Right Electrical Lockout Equipment

Circuit Breaker Compatibility: Different breakers require specific lockout devices. Universal mini lockouts suit most standard MCBs, whilst larger breakers may need pin-in or grip-tight devices. Always verify compatibility with your specific switchgear before purchasing.

Individual or Group Lockout: Solo workers may require only individual padlocks and lockout devices, but sites with multiple personnel working on the same circuit need lockout hasps accommodating several padlocks simultaneously, ensuring everyone's safety.

Complete Kits vs Individual Components: Mobile electricians benefit from comprehensive lockout kits in carry cases containing everything needed, whilst fixed facilities may prefer wall-mounted lockout stations. Alternatively, build custom solutions with individual components suited to your specific requirements.

Padlock Security: Choose lockout padlocks with keyed-different cylinders so each worker has a unique key. Look for non-conductive bodies, high-visibility colours, and adequate shackle clearance for your application.

Durability and Standards: Ensure equipment meets HSE requirements and relevant BS EN standards. Consider your working environment – industrial settings may require heavy-duty steel construction, whilst lighter aluminium options suit less demanding applications.

Safety Information

The Electricity at Work Regulations 1989 require electrical systems be made dead before work begins. Always follow proper isolation procedures: identify all energy sources, shut down equipment, apply lockout devices, dissipate stored energy, and verify isolation with appropriate voltage testing equipment. Never remove another person's lock – this fundamental LOTO rule prevents circuits being re-energised whilst others are still working. Always use lockout tags alongside physical lockout devices to document who performed the isolation, when, and why. Regular inspection of lockout equipment is essential – replace any damaged items immediately as compromised devices may fail when needed most.

Frequently Asked Questions

Can I use a standard padlock for electrical lockout?

Whilst standard padlocks may physically work, dedicated lockout padlocks are specifically designed for LOTO procedures. They feature non-conductive bodies, high-visibility colours (typically red), keyed-different options for individual accountability, and construction designed to withstand industrial environments. For proper HSE compliance and maximum safety, MyToolShed.co.uk recommends always using purpose-designed lockout padlocks.

What's the difference between lockout and tagout?

Lockout involves physically securing an isolation point with a lock to prevent operation, whilst tagout uses warning tags to indicate equipment should not be operated. UK HSE guidance emphasises that tags alone provide insufficient protection – physical lockout devices must be the primary safeguard, with tags providing supplementary information about who locked out the equipment and why.

What size circuit breaker lockout do I need?

Circuit breakers vary considerably in size and design. Measure your specific breakers or check their specifications before purchasing. Universal mini circuit breaker lockouts fit most common MCBs found in UK distribution boards, whilst larger breakers may require grip-tight or pin-in devices designed for specific breaker styles and pole widths.