Dies

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Dies

Dies are precision cutting tools designed to create external threads on pipes, rods, bolts, and cylindrical bar stock. Essential for plumbers, engineers, and fabricators, threading dies enable accurate thread formation to British standards including BSP (British Standard Pipe), BSPT (British Standard Pipe Taper), metric, and UNC specifications. MyToolShed.co.uk stocks a comprehensive range from trusted manufacturers including Dormer, Ridgid, Sirius, Draper, and Faithfull, covering both manual and machine threading applications.

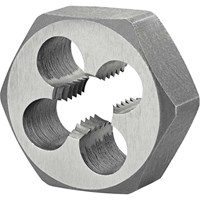

Available in various configurations including circular split dies with adjustable openings, solid dies for rigid precision work, and hexagonal die nuts that can be turned with standard spanners, these tools work with die stocks or threading machines to cut clean, accurate threads. Manufactured from HSS (High-Speed Steel) for durability and edge retention, quality dies maintain their cutting performance through thousands of threading operations when properly maintained with cutting fluid. Whether you need dies for on-site pipe repairs, fabrication work, or restoring damaged threads, MyToolShed stocks individual dies and comprehensive sets suitable for professional and serious DIY applications.

Applications

- Plumbers and heating engineers – threading copper and steel pipework, creating custom pipe lengths, repairing damaged threads

- Maintenance engineers – restoring threads on machinery, creating replacement threaded components

- Mechanical fitters and fabricators – threading studding, bar stock, and custom fabrications for assembly work

- Gas fitters – threading gas supply pipes to BSPT standards for pressure-tight connections

- Vehicle mechanics – repairing stripped threads, creating mounting points on automotive equipment

- Agricultural and marine engineers – maintaining threaded connections on farm machinery and vessels

- General engineering – producing bespoke threaded components where pre-threaded parts are unavailable

- DIY enthusiasts – home plumbing projects, workshop fabrication, equipment repairs

Choosing The Right Dies

Thread Standard: Identify the correct thread type for your application. BSP and BSPT are standard for UK plumbing work, metric threads suit general engineering, whilst UNC/UNF threads are required for American-specification equipment. Using incorrect standards results in incompatible, unsafe connections.

Die Configuration: Circular split dies offer diameter adjustment and work with die stocks for general workshop use. Solid dies provide rigid accuracy for precision threading. Die nuts offer convenience for field repairs using standard spanners, whilst threading machine dies are designed for powered equipment handling larger diameter pipes efficiently.

Material and Quality: HSS dies handle most common materials including mild steel, brass, copper, and aluminium. Professional-grade dies from Dormer, Ridgid, and Sirius available at MyToolShed.co.uk offer superior edge retention and accurate thread profiles compared to budget alternatives that may produce inconsistent threads or fail prematurely.

Size and Pitch: Verify both thread diameter and pitch match your requirements. Use thread gauges to identify existing threads when making repairs or extensions. For new applications, consult British Standards or manufacturer specifications.

Safety Information

Always wear safety glasses to protect against metal chips and work gloves when handling workpieces. Securely clamp materials in a vice – never hand-hold workpieces during threading operations as this risks serious lacerations. Use appropriate cutting fluid to reduce heat build-up and prevent die damage. When operating threading machines, ensure guards are fitted, keep hair tied back, and avoid loose clothing or jewellery that could become caught in rotating components. Inspect dies regularly for damage or worn cutting edges. Never force a die – withdraw, clean threads, apply more lubricant, and proceed gradually if excessive resistance occurs.

Frequently Asked Questions

What's the difference between BSP and BSPT threads?

BSP threads are parallel and typically require washers or O-rings to seal, whilst BSPT threads have a 1:16 taper that creates an interference fit, forming pressure-tight seals when tightened with sealant paste. BSPT is preferred for gas installations and high-pressure applications requiring reliable seals.

Do I need cutting fluid when using threading dies?

Yes, cutting fluid is essential for producing clean threads and extending die life. It reduces friction, dissipates heat, and evacuates metal chips. General cutting oil suits steel, whilst neat cutting fluid or paraffin works better for aluminium and copper. Threading dry produces rough threads and accelerates die wear.

Can dies be used to repair damaged threads?

Yes, dies excel at chasing or cleaning damaged external threads, removing rust, paint, or minor damage. Split dies are preferable as they can be adjusted to cut minimally, preserving original thread material. Run the die over threads several times with cutting fluid until smooth engagement is restored.