Aerosol Spray Paints

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Aerosol Spray Paints

Aerosol spray paints provide professional finishing results without expensive spray equipment, making them essential for tradespeople and DIY enthusiasts working across diverse applications. From quick touch-ups on structural metalwork to complete transformations of garden furniture, these pressurised canisters deliver consistent, even coverage that's particularly effective on intricate details, awkward angles, and hard-to-reach surfaces. MyToolShed.co.uk stocks seventeen specialist subcategories, ensuring the perfect formulation for every substrate and project requirement.

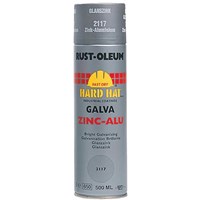

Modern aerosol technology extends far beyond basic colour application, incorporating advanced performance characteristics tailored to specific trades and environments. Anti-corrosion formulations protect exposed steelwork, galvanizing sprays provide cathodic protection on ferrous metals, whilst line marking aerosols deliver high-visibility safety markings for car parks and warehouses. Available across gloss, satin, and matt finishes in extensive colour ranges—including fluorescent and metallic options—aerosol spray paints suit applications from architectural metalwork and vehicle bodywork to shopfitting and property maintenance.

Applications

Aerosol spray paints serve numerous trades and industries requiring quick, professional finishing:

- Metal Fabricators & Welders: Coating structural steelwork, balustrades, gates, and bespoke metalwork with protective finishes

- Vehicle Body Shops: Spot repairs, primer application, and colour matching for automotive refinishing

- Maintenance Engineers: Touch-ups and repairs to machinery housings, equipment frames, and industrial installations

- Shopfitters & Joiners: Finishing metal fixtures, architectural details, and display systems on commercial fit-outs

- Facilities Managers: Line marking, safety signage, and general maintenance across commercial premises

- Property Maintenance Teams: Rapid refurbishment work on rental properties and commercial buildings

- Landscape Gardeners: Renovating outdoor furniture, railings, and decorative metalwork exposed to weathering

- DIY Enthusiasts: Home improvement projects from furniture restoration to creative upcycling

Choosing The Right Aerosol Spray Paints

Surface Material: Different substrates demand specific formulations for proper adhesion. Bare metal surfaces typically require specialist metal primer before topcoating, whilst plastic needs paints with adhesion promoters to prevent peeling. Wood, masonry, galvanised steel, and previously painted surfaces each have distinct requirements.

Environmental Exposure: Exterior applications demand weather-resistant formulations with UV stabilisers to prevent chalking and colour fade, whilst items exposed to moisture require anti-corrosion properties. Interior projects may prioritise low-odour, reduced VOC content for occupied spaces.

Finish Type: Gloss finishes provide maximum durability and easy cleaning, ideal for metalwork and high-traffic areas. Matt finishes offer excellent coverage whilst hiding surface imperfections, whilst satin finishes compromise between the two. Specialist options like hammertone add distinctive texture that disguises irregularities.

Drying Time: Fast-drying formulations touch-dry within 10 minutes, essential for time-sensitive site work or when multiple coats are needed quickly. Standard formulations require longer but often provide superior flow for the smoothest possible finish.

Special Properties: MyToolShed.co.uk stocks formulations with specific characteristics including heat resistance for radiators, anti-slip additives for floor applications, galvanizing protection for exposed steelwork, and high-visibility fluorescent shades for safety marking.

Safety Information

Ventilation: Always work in well-ventilated areas to prevent solvent vapour accumulation. For indoor applications, ensure adequate air movement and consider extraction equipment to meet COSHH requirements.

Respiratory Protection: Use HSE-approved respirators when spraying, particularly with solvent-based paints. Select respirators with appropriate cartridges rated for organic vapours and particulates.

Fire Safety: Aerosol paints are extremely flammable. Keep away from ignition sources, naked flames, hot surfaces, and sparks during application and whilst drying. Store canisters away from direct sunlight, never exceeding 50°C.

Disposal: Never puncture or incinerate aerosol cans, even when empty. Dispose of spent canisters responsibly according to local authority guidelines for hazardous waste.

Frequently Asked Questions

How many coats of aerosol paint do I need?

Most applications require 2-3 thin coats rather than one heavy coat for optimal results. Thin layers dry faster, reduce runs and sags, and provide more durable adhesion. Always observe recoat times specified on product labels—typically 10-30 minutes between coats for fast-drying formulations.

Do I need primer before applying aerosol paint?

Primer proves essential for bare metal, plastic, galvanised surfaces, and other challenging substrates to ensure proper adhesion and longevity. It also improves coverage, particularly when applying light colours over dark surfaces. Whilst some aerosol paints incorporate primer properties, separate priming generally delivers superior professional results.

What's the best temperature for spraying aerosol paint?

Optimal conditions fall between 10-25°C with low humidity. Cold temperatures slow drying times and affect flow characteristics, whilst excessive heat causes rapid solvent evaporation leading to rough, textured finishes. Both the canister and surface being painted should be at similar temperatures for best results.